Emerald cut is most difficult shape in all fancy cut diamonds shape to cut to polish with maximum light performance, and it’s because of its Pavilion and Crown Step combination. Mostly there are two types of emerald which currently manufacture by industry most,

1) 4 Step Emerald cut

2) 3 Step Emerald Cut.

In 4 Step Emerald cut, there are 4 step in pavilion and 3 steps in crown. As you can see in below images some of best looking Emerald 4 Step cut diamond images. We are working since last 7 years to develop standards step of parameters in which we achieved maximum light performance in emerald cut diamond. It’s very important to maintain angle difference in each of Pavilion and Crown steps in Emerald while polishing to maintain its fire and make looks beautiful in hands.

We make complete lab (parameters) guidance for manufacture and polishing to follow and get maximum performance in any Emerald cut diamond.

This Emerald Cut diamond is not best looking emerald, as you can see that due to light block while viewing stone from face-up it make this Emerald looks dark with heavy contract in center. To improve such Emerald Cut Diamond it’s very important to make sure each and every facet should be polish at angle which reduce heavy contract in center for emerald cut diamonds.

We develop parameters after studying this and finally come with software and guideline parameters which help manufacturing to make sure no Emerald cut diamond get polish with heavy contact (leakage) in center.

As we can see most of Emerald diamonds have heavy contact in center which block the light and make it looks dark from center.

Challenges for Emerald Cut Parameters.

- No tool available to check Emerald Cut light virtually.

- No standards set of parameters available by any lab or other company which help manufacturing to follow and make beautiful cut emerald diamond.

- Lack of knowledge and standards method to judge Light in Emerald cut polish diamond.

We work on all above the challenges and come with solutions. Our software and service help to improve your quality of emerald cut and bring maximum fire on all Emerald Cut which manufacturing by you.

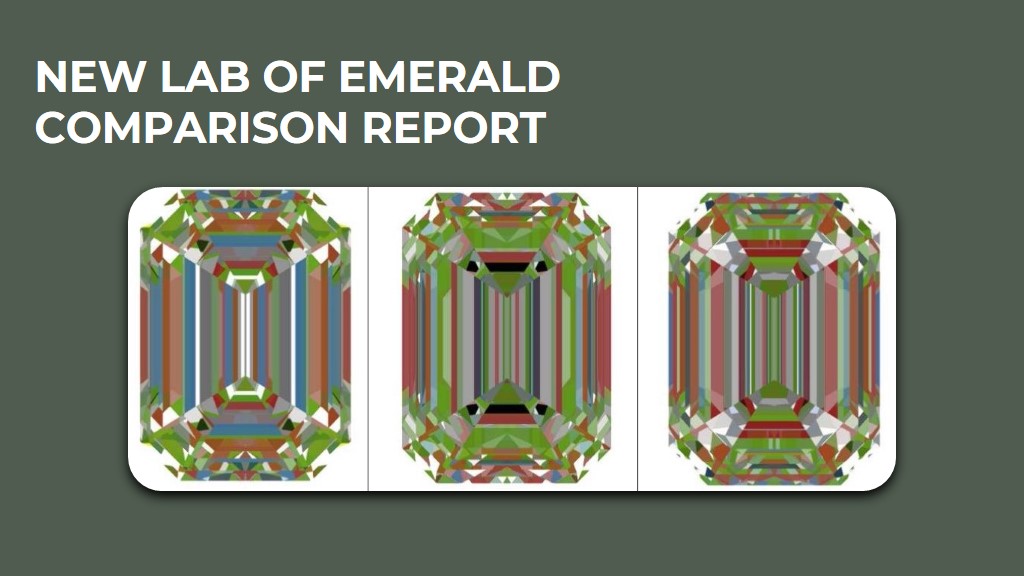

New Lab of Emerald Comparison Report Dt: 16-12-2019

Project Name: 153+1+MK

In any Rough scanner parameters Lab is may very important role. As currently most of diamond companies using Sarin or Octonus / Lexus rough planning scanners. All rough planning systems are accurate and give optimal results only when there parameters lab is accurate and match the needs of rough model.

We understand the needs of our clients and develop new Rough Parameters Lab for planning systems to achieve Best Light Performance while rough stage. This Lab helps to get best light performance and weight at rough planning stage.

In this Project, we getting more weight and light, as you can see in EX-2 plan we getting best light and Corner are also narrow which make stone look bigger. In EX-3 we getting more weight due to its corner as corner are wide.

(As you can see in above chart you can see some of combination which is very closer but still performance much better then there near ones)

Project Name: 3_E+2MK

Project Name: 70-3-VMK

Project Name: 32+334MK